Use Digitization to Transform Chemical Supply Chain Planning

How to Elevate Your Logistics Operations with AI & ML Technology

Global supply chain organizations are embracing digitization to propel their supply chain planning to new heights. This transformation is not just a technological upgrade but a strategic move to foster innovation and support the ambitious growth goals of the organization.

Within the chemical industry, challenges such as regulatory compliance, market volatility, and stringent safety measures require innovative solutions. The need for solutions is where the power of digitization comes into play, addressing these challenges head-on. Whether achieving real-time compliance tracking, navigating market uncertainties through advanced analytics, or reinforcing safety protocols via secure data exchange, the digital revolution within the chemical supply chain emerges as the critical factor in surmounting these difficulties.

What is Supply Chain Planning?

Supply chain planning is the process of efficiently and effectively managing the entire lifecycle of a product or service from its initial design and development through production, distribution, and, ultimately, delivery to the end customer. Supply chain planning aims to ensure that the right products are available at the right place, time, and quantity while minimizing costs and optimizing overall efficiency. Companies that have streamlined their supply chains experience a 15% reduction in supply chain costs, maintain inventory holdings below 50%, and achieve cash-to-cash cycles that are three times faster.[1]

Chemical supply chain planning specifically refers to applying supply chain planning principles and strategies within the context of the chemical industry. The chemical industry is characterized by the production and distribution of various chemical products, including raw materials, intermediates, and finished goods. Managing the supply chain in this industry involves unique challenges and considerations due to the nature of chemical products, regulatory compliance, and safety requirements.

Components of the Supply Chain Planning Process

Planning in supply chain management is of the utmost importance for sustained success. Select components form the backbone of a well-orchestrated supply chain, allowing businesses to respond adeptly to market demands, mitigate risks, and optimize resources for sustained success. These components include:

Demand Forecasting

Accurate prediction of customer demand is the cornerstone of effective supply chain planning. It involves analyzing historical data, information such as market trends and other relevant factors, and the knowledge to anticipate future demand accurately. Data informs transportation capacity and rates. The information identifies the opportunities and inefficiencies in a particular spend market. Knowledge pulls in specific rate structures and data points to determine how to save costs. For the best Demand Forecasting decisions, use transportation-managed analytics such as those outlined below.

Inventory Management

Balancing inventory levels is essential to avoid stockouts or excess stock. Efficient inventory management ensures that the right products are available at the right time, minimizing costs and maximizing customer satisfaction.

Response & Supply Planning

This component focuses on crafting responsive strategies to address unexpected disruptions in the supply chain, ensuring that the production and delivery processes remain agile and adaptable.

Sales & Operations Planning (S&OP)

S&OP involves aligning sales and operational teams to make informed production, inventory, and distribution decisions, optimizing overall business performance.

Demand-Driven Replenishment (DDMRP)

DDMRP is a method that combines planning and execution to synchronize supply chain processes with actual demand, promoting flexibility and reducing lead times.

Supply Chain Monitoring

Monitoring and analyzing key performance indicators (KPIs) is crucial for identifying bottlenecks, optimizing processes, and ensuring continuous improvement in planning and supply chain management processes.

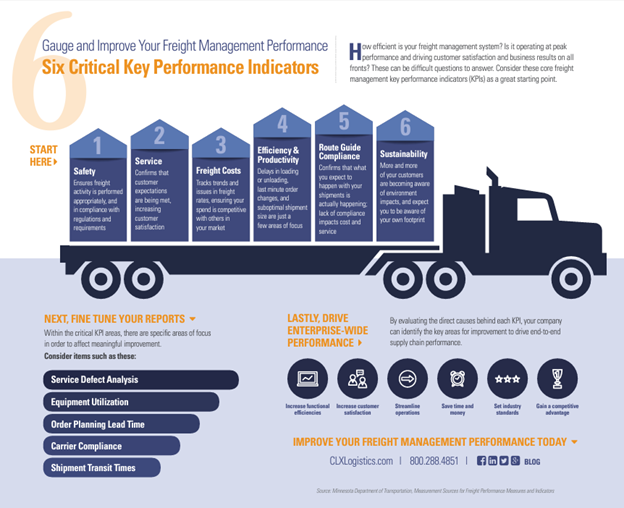

How efficient is your freight management system? Is it operating at peak performance and driving customer satisfaction and business results on all fronts? These can be difficult questions to answer. Consider these six core freight management KPIs as a great starting point:

Supply Chain Digital Transformation

The integration of digital technologies has become a catalyst for profound transformations across various sectors, and the supply chain management industry is no exception. The strategic implementation of advanced technologies has brought about a paradigm shift to enhance efficiency, visibility, and agility in the entire supply chain ecosystem. This transformative journey encompasses a spectrum of innovative tools, including artificial intelligence (AI), the Internet of Things (IoT), blockchain, and data analytics, which collectively revolutionize traditional supply chain models.

Supply chains incorporating AI technologies demonstrate a 67% increase in efficiency compared to conventional supply chains that don’t leverage AI.[2] Hence, it is no surprise that a recent industry survey found that 97% of respondents anticipate AI’s influence on product development and manufacturing.[3] Of these, 85% have already embraced these technologies or are actively in the adoption process. As organizations embrace this digital evolution, they streamline operations and gain a competitive edge by staying ahead of the curve.

Challenges Faced by Chemical Supply Chain

The chemical industry faces unique challenges in its supply chain, including regulatory compliance, volatile market conditions, and the need for stringent safety measures. Digitization offers a comprehensive solution to better manage and optimize for these challenges.

How the Digitization of Supply Chains Solves Issues Faced by Chemical Logistics

This digitization resolves specific challenges and brings about a holistic transformation, optimizing processes, improving compliance, and fortifying safety measures.

- Regulatory Compliance: Digitizing supply chain processes allows for real-time tracking and documentation, ensuring compliance with regulations throughout the supply chain.

- Market Volatility: Advanced analytics and forecasting tools powered by artificial intelligence (AI) and machine learning (ML) help anticipate market changes and proactively adjust supply chain strategies.

- Safety & Security Concerns: Digital solutions enable the implementation of robust safety protocols, traceability, and secure data exchange, mitigating risks and ensuring the integrity of the supply chain.

- Complex Logistics: Digitization provides visibility into the entire supply chain, allowing for better coordination and communication among stakeholders, thereby simplifying complex logistics.

Dive deeper into how Transportation Managed Analytics is building and managing next-generation supply chain’s by finally answering the questions that close the gap between visibility, performance, spend and risk.

Whitepaper: Rethinking Supply Chain Performance with Transportation Managed Analytics

Planning for a Supply Chain Digital Transformation

Incorporating digital technologies into your supply chain is beneficial if you plan well and leverage them correctly. Embarking on a supply chain digital transformation journey requires careful planning and strategic implementation. Here are the key steps:

- Create a Plan Based on Business Goals: Developing a comprehensive plan that aligns digitization efforts with overarching business goals is paramount. It involves identifying specific objectives such as cost reduction, improved customer satisfaction, or increased operational efficiency. The plan should also consider the long-term sustainability and adaptability of the digital transformation initiatives.

- Evaluate Existing Systems: A thorough assessment of current supply chain systems, technologies, and processes is essential. It involves identifying inefficiencies, bottlenecks, and areas where technology can bring about significant improvements. Additionally, it’s necessary to consider the compatibility and interoperability of existing systems with new digital solutions.

- Gain Stakeholder Buy-In: Engaging key stakeholders early in the planning process is crucial to understanding their concerns and expectations. Clear communication of the benefits of digital transformation to executives, managers, and employees is essential. Establishing a collaborative approach to decision-making ensures support at all levels of the organization.

- Unify Data for Supply Chain Visibility: Integrating data from various sources, such as suppliers, manufacturers, and distributors, is fundamental to creating a centralized data repository. Your company should implement real-time tracking and monitoring systems to enhance visibility across the supply chain. Increased visibility facilitates data-driven decision-making by ensuring data accuracy and accessibility.

- Automate Routine Processes: A critical step is to identify repetitive and time-consuming tasks in the supply chain workflow that your company can automate. Implementation of robotic process automation (RPA) or other automation technologies is necessary to streamline operations. The focus should be on reducing manual errors, improving accuracy, and accelerating the pace of routine processes.

- Take Advantage of AI- & ML-powered Analytics: Implementing artificial intelligence (AI) and machine learning (ML) tools to analyze large datasets and extract actionable insights is pivotal. Leveraging predictive analytics enhances demand forecasting, inventory management, and overall decision-making. Continuous learning from data patterns and adapting to changing conditions optimize supply chain operations.

- Train Teams on New Technology: Investing in comprehensive training programs to equip employees with the necessary skills to operate and leverage new technologies is essential. Providing ongoing support and resources facilitates a smooth transition to digital tools and systems. Fostering a culture of continuous learning ensures that teams stay updated on the evolving technology landscape and can adapt to future changes.

How well do you know your data? Check out CLX GravityTM, a proprietary platform that helps companies understand their supply chain analytics and optimize their supply chain.

Choose CLX to Improve Your Chemical Supply Chain Planning

While the efficacy of AI and ML in addressing the distinctive challenges of chemical logistics is evident, achieving a seamless integration of these technologies for comprehensive efficiency optimization can pose challenges. Optimizing your supply chain management requires a deep understanding of the industry and the relevant technology.

With expertise in AI and ML for addressing unique challenges in chemical logistics, our globally trusted chemical logistics division, CLX Logistics®, specializes in transportation solutions tailored to special regulatory, safety, and security requirements. From strategic design to operational support, our comprehensive supply chain consulting and transportation management services (including intermodal transportation solutions) optimize efficiency and savings. Partner with CLX to stay ahead in the digital transformation, gaining a competitive edge for sustained success in the chemical industry.

Are You in Control of Your Logistics Spend? CLX Gravity™ Can Answer That Question… And More!

CLX Gravity™ is an analytics platform that significantly improves transportation visibility by combining data from multiple systems within your business with data already available through CLX Global TMS™. This application provides a holistic view of your global supply chain while allowing CLX Logistics® to analyze information in a new way.

- Increase the value of your transportation spend faster than ever before

- Reduce IT involvement in your data analysis

- Reduce costs and complexity of combining and managing disparate systems

Connect with us to elevate your chemical supply chain management.

[1] The State of Supply Chain Management – Statistics and Trends

[2] AI set to transform supply chain management – Industry roundup: 13 April

[3] 2023 State of Manufacturing Report

Back to Resources