By Cosmas Hoefnagels for Talking Logistics

As digitization continues to modify the global supply chain landscape, its unprecedented data sources and solutions will lead to not only the demise of disparate information systems, but to the rise of true, end-to-end, supply chain visibility. For suppliers and mid- to large-sized companies, supply chain visibility serves as the foundation for strategic decisions and tactical improvements across the entire transportation network. It is through the establishment of supply chain visibility that supply chain insights, outside the four walls, will be garnered and leveraged as actionable data that supports supply chain optimization.

Today, companies have varied interpretations of “visibility,” largely due to evolving business demands and globalization trends. To an international 3PL in 2016 however, supply chain visibility (SVC) is known as the capability to monitor and register movements through a transportation network. This functionality then leads to supply chain insight which allows companies to learn about operational performance, strengths and weaknesses of a supply chain configuration, changes in supply or demand and customer service capabilities and cost.

While some industries have already achieved this ideal state of transparency, businesses in the chemical industry for example, that are better known for well-developed IT infrastructures or plant operations and less for the adoption of advanced supply chain concepts and optimization, are begetting one key question: how do we approach and achieve end-to-end supply chain visibility, and ultimately benefit from the network-wide insights it will offer? To these companies we say, follow these five steps.

1. Define Your Unique Corporate Goals and Objectives

Much like any other strategic initiative or company-wide process change, leadership must start with the end in mind. Consider the ways rich data collection can help shape your supply chain towards lower cost and optimal performance. The most common goals of supply chain visibility include the following, but as your company completes this exercise, be sure to include quantifiable metrics:

- Reduce business and supply chain risk

- Improve lead times and performance

- Identify shortage and quality problems along the supply chain

2. Augment and Set Visibility Tools In Place

The first tangible step towards achieving SCV is to get the basic visibility tools in place. These tools include sophisticated IT platforms such as enterprise resource planning (ERP) software; electronic data interchange (EDI); or transportation management systems (TMS). For companies with existing supply chain technology, it is likely not necessary to collect new data, but to take a fresh look into a data warehouse through unused add-on and field functionalities. For international companies with multiple locations or scarce technology, it is often a best practice to seek the expertise of an experienced 3PL provider to recommend and integrate the ideal platform into your supply chain.

3. Track, Trace and Collect Data from Key Partners

Configure your visibility tools to establish data collection among key partners, such as suppliers, service providers, contract manufacturers and customers – all of which are focused namely on supply chain logistics functions. As data is collected from these primary and secondary parties, be sure to also integrate it with your global track and trace strategies to deliver cross-functional insights that can deliver return-on-investment.

4. Analyze Performance and Manage Expectations

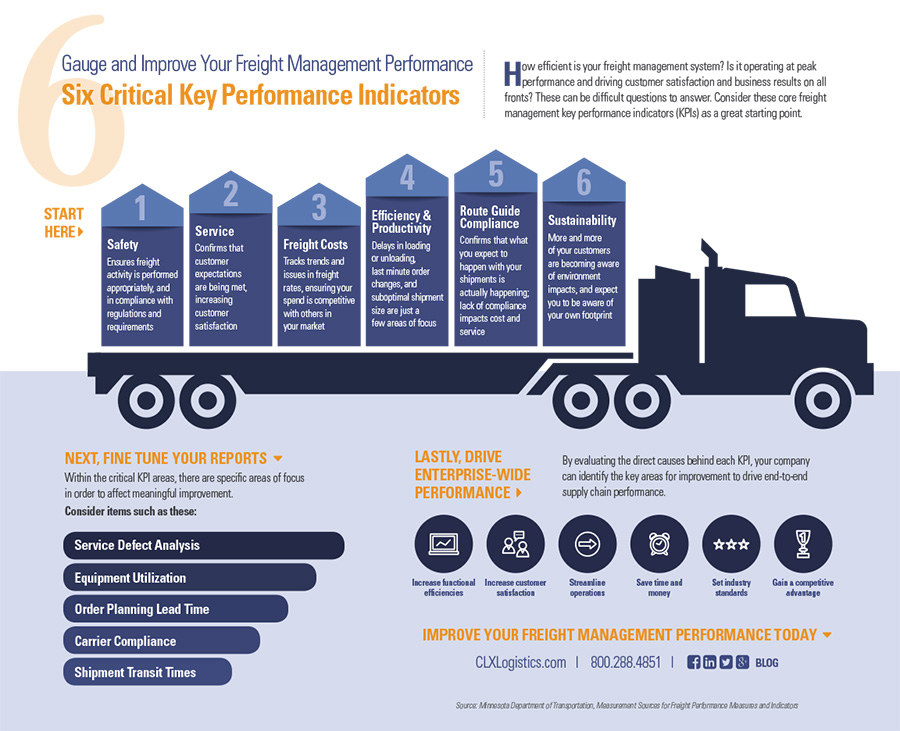

With your data collection and visibility needs aligned, your company should leverage dashboards and scoreboards to not only monitor KPIs, but the bigger picture which includes enterprise-wide and outside the four walls workflows. For example, leverage your technology to track workflow events from purchase order to fulfillment and provide access to people beyond the primary addressees, such as trading partners and suppliers. This expanded accessibility is the key to fostering outside the four walls visibility, allowing data to be analyzed from myriad perspectives. The outcomes of knowledge-sharing at this level will strengthen relationships, drive new applications, improve contract negotiations, mitigate bottlenecks and uncover additional, unforeseen improvement areas.

5. Optimize from End-to-End with Business Intelligence

Upon analyzing the performance of your supply chain against different perspectives, your company will gain usable intelligence to improve basic operational measures and develop alternative supply chain strategies. This actionable data can be used to not only anticipate changes to supply and demand, but to remodel the supply chain and calculate alternative configurations and delivery networks, including inbound shipments and consolidation opportunities. Furthermore, once a well-fitted information system has been established, it is time to develop and adhere to regular evaluations and reviews to ensure continuous improvement and optimization is firing, and integrating, on all cylinders.

In a recent Kewill survey, more than one-third of organizations indicated they are planning to broaden workflow visibility outside the four walls. With almost half of the organizations surveyed seeking greater visibility and insight, it is palpable that digitization is not just challenging businesses to progress, but inspiring companies to adopt alternative approaches to supply chain optimization. So, while leaders may “start with the end in mind” to set their organization up for success, there are just as many organizations discussing the benefits of “first things first”— and that is supply chain visibility.

Read full article here.